section-00087c8

section-e9a4d85

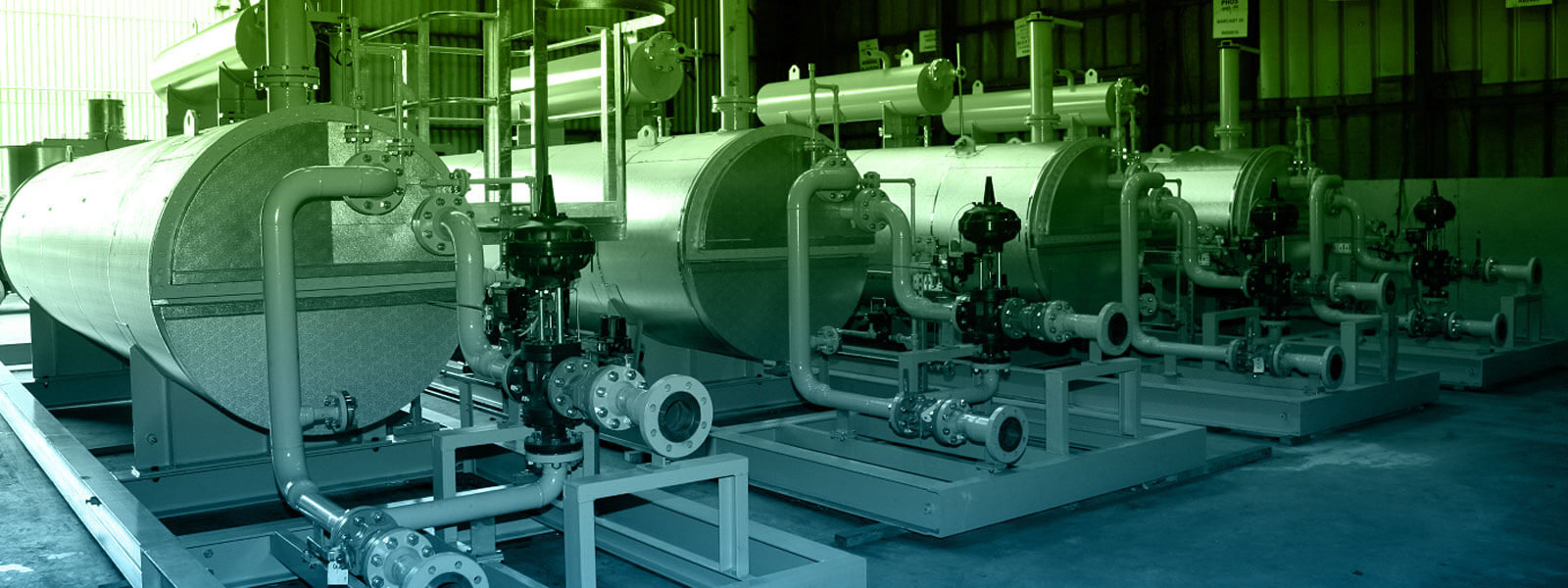

Water Bath Heaters

Water bath heaters are indirect fired heaters that heat the desired application through a process coil submerged in a heated water-glycol, or salt solution depending on the required heat output temperature. The bath fluid is heated indirectly from a single or multiple fire tube design that is connected to a burner to produce the heat source.

Water bath heaters have been a common solution of process heating for years in various industries providing reliable and safe operations in the field and high-risk areas, as well as being an operator-friendly system.

Generally, water bath heaters are used for heating oil or gas and common designs are in line with API12K, though there are many options to customise a bespoke water bath heater to customer requirements, or specific application demands that still conform to international standards.

Integraheat offers a range of designs in water bath heaters to accommodate efficiency, optimised reduction in emissions and cost-sensitive budgets. One major benefit of an Integraheat water bath design is that we have the expertise and technology to supply the burner which is fully designed, manufactured, and guaranteed by Integraheat. In most cases heater design and supply companies rely on the design and assistance of a combustion or burner company to provide the burner to their heater design, this approach leads to complications in some cases where the liability cannot be defined in the event of any performance issues. We believe that when supplying our water bath heaters, the book stops with us as we have full responsibility for the design of the complete heater, burner, and control system with only secondary components being relied on from suppliers. In turn, this results in customer comfort that the design of the full system is from one company that understands its functionality and capabilities to service and support the systems expectations.

What does an Integraheat water bath heater consist of?

- Shell

- Firetube

- Exhaust Stack

- Process Coil

- Burner

Water Bath Heating Applications

- Wellhead Heater

- Gas Heating Applications

- Transmission / Distribution System Heaters

- Crude Oil Heating Applications

- Vaporising LPG & LNG

- Regeneration Gas Heating

- Dew Point Heating

Design Options

- Natural Draft Burner

- Forced Draft Burner

- Dual Fuel Burner

- Air Controlled gas

- Remote Monitoring

- Low to High Spec Area Classifications

- Simple or Complex Control Systems

Shell

The heater shell is typically fabricated of carbon steel and formed into multiple saddle type supports depending on the length. The shell can in some cases be standalone where the saddles are directly fixed to foundations at site, or the saddles can be connected to a skid structure. The option for lifting points are normally from the skid, though may be from the shell where a skid is not desired. The shell is designed in a way that allows for easy insertion and extraction of the coil & firetube for maintenance and inspection purposes.

The heat transfer medium in the shell may be water, water/glycol mixture, steam, oil [natural or synthetic] or complex mixes of synthetic fluids. Water is the most common bath solution, and it can be operated at temperatures of up to 90 oC. Water and glycol mixtures are also used depending on the environmental conditions and customer requirements. If it is required to meet high process fluid outlet temperature, thermal fluids or salts can be used as they can be operated at higher temperatures than 90 oC.

Firetube

We provide the most optimum firetube configuration meeting the code requirements for the heat flux as well as the requirements for the natural or forced draft types for designs of increased thermal efficiencies. The firetube assembly may consist of a U-tube/serpentine configuration or a design with a main firetube and multiple returns, which will bring the flue gas back to a common gathering box and releasing flue gas into the stack, which will significantly increase the efficiency of the heater. The length of the firetube will depend on the overall design of the heater. The firetube is positioned in the bottom section of the heater shell and connected by a flange to the shell for ease of maintenance and servicing through the assets lifecycle. In some cases, expansion bellows maybe inserted to absorb dimensional changes during expansion and contraction of the heat intensity.

Exhaust Stack

The exhaust stack is generally mounted on the flue gas gathering box that is welded to the firetube cover plate and collects the flue gas from the return firetubes, and may be grade mounted in some instances. We design stacks meeting the minimum stack height with high discharge velocities for pollution reasons A maximum stack height to limit visual impact in scenic areas or both is considered during the design phase. Based on this information and on the type of burner required, a decision can be taken on whether to run the heater on natural or forced draft.

Process Coil

The process coil operates under more than atmospheric pressure and is fabricated from seamless pipe and in accordance with ASME Section VIII, Div 1. The process coils are attached to a common flange plate that connects to the shell, this places the coil directly above the firetube where both the coil and firetube are connected to the shell at opposite ends. With the coil in the hottest portion of the heater, this assures the most efficient heat transfer. All coil welds are 100% radiographed to ensure safety and reliability.

Burner

The burner is a key part of the water bath heater design to ensure efficiency and optimised emissions reduction. All Integraheat water bath heaters are designed so as the firetube flange connection accommodates the full range of Integraheat burners. Our burners are offered in the natural draft or forced draft depending on the heater requirements. Integraheat burners are in line with industry efficiency goals and meet low NOx performance.